A functioning framework guarantees a successful outcome

Heavy and medium-heavy steel structures reliably and professionally!

When there is enough space, work flows smoothly and projects remain under control.

Our machine shop’s 16,000 m² versatile production facilities provide an excellent framework for the manufacture of heavy and medium-heavy steel structures. Large, clear halls and robust lifting capacity (80 t in the hall, over 100 t in the port) enable efficient handling of even large structures from start to finish – without unnecessary transfers or delays.

Our entire production chain takes place under one roof. This means smooth project management, efficient lead times and complete certainty about delivery schedules. The facilities are designed for the needs of industry – no compromises, but operational reliability.

When space is not a constraint, we can implement even complex entities sensibly and without compromising on quality. This benefits both the end customer and every operator in the chain.

Our own port brings smoothness and savings to logistics

We are located by the sea in Pargas and we have our own port. This means that heavy and space-intensive structures can be delivered directly by sea without intermediate storage or separate transport costs. Our lifting capacity is over 100 tons, and the port is equipped for efficient loading and unloading.

The port connection brings flexibility, especially for projects where structures are taken directly to shipyards, for export or to demanding sites around the world. Direct sea transport saves time, reduces risks and optimizes the entire supply chain.

When transport is part of our own entity, project management also remains in our hands – from start to finish.

16 000 m² production facilities

Almost 40 years of experience

Certified expertise

Own port -

lifting capacity over 100t

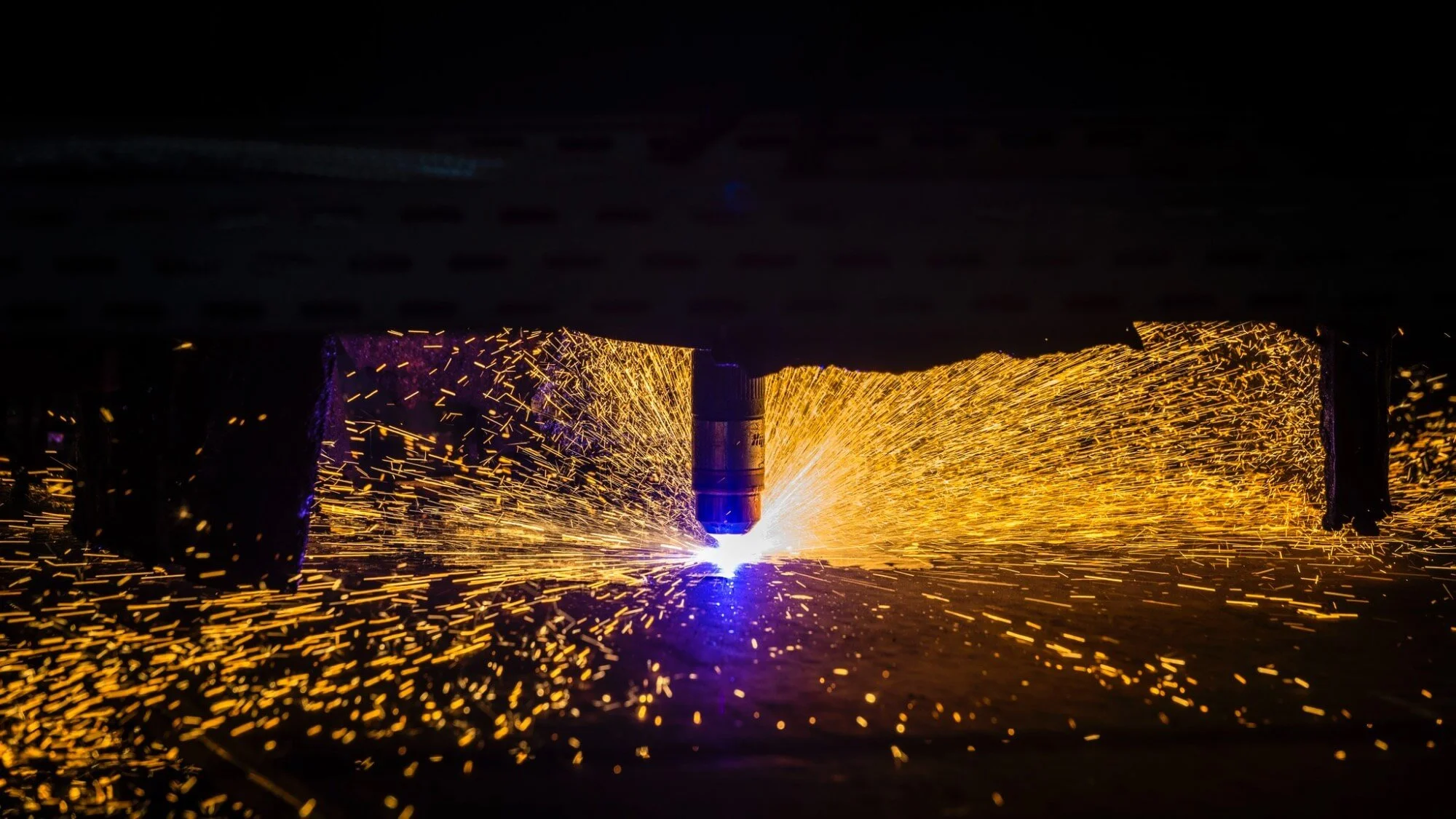

Our tools match the job and our expertise makes them efficient.

Our machinery is designed for the production of heavy and medium-heavy steel structures. We have a wide range of sheet metal working machines, sturdy mangles, CNC-controlled cutting, bending and drilling machines, as well as modern welding and heat treatment equipment. In our own steel shot blasting and painting shop, we ensure that the end result is high-quality and finished.

In practice, this means that we can carry out large and multi-stage projects under one roof – efficiently, accurately and without unnecessary interruptions. We also have strong experience in machining and handling large structural components. For example, submerged arc welding, versatile drilling capacity and mangling of large plates are part of everyday life, not special requests.

The machinery is in good condition – but the decisive factor is knowing how to use it correctly. We carry out our work with high quality right through to the end.